Who we are

Our Company

Our company is in Buje, in the northern part of Istria, north of Croatia. Stilla Coloris comes from the Latin and means drop of colour. Our reality was born in 2014 from a previous company with many years of experience in the regeneration of cartridges. The new property maintained these experience and these skills acquired over the years, ensuring high quality standards and efficiency.

The process stems from a sorting and cleaning cycle, which allows us to select the regenerable material, giving it a second chance.

It is in our laboratory where the magic happens!

Our Team

Production Steps

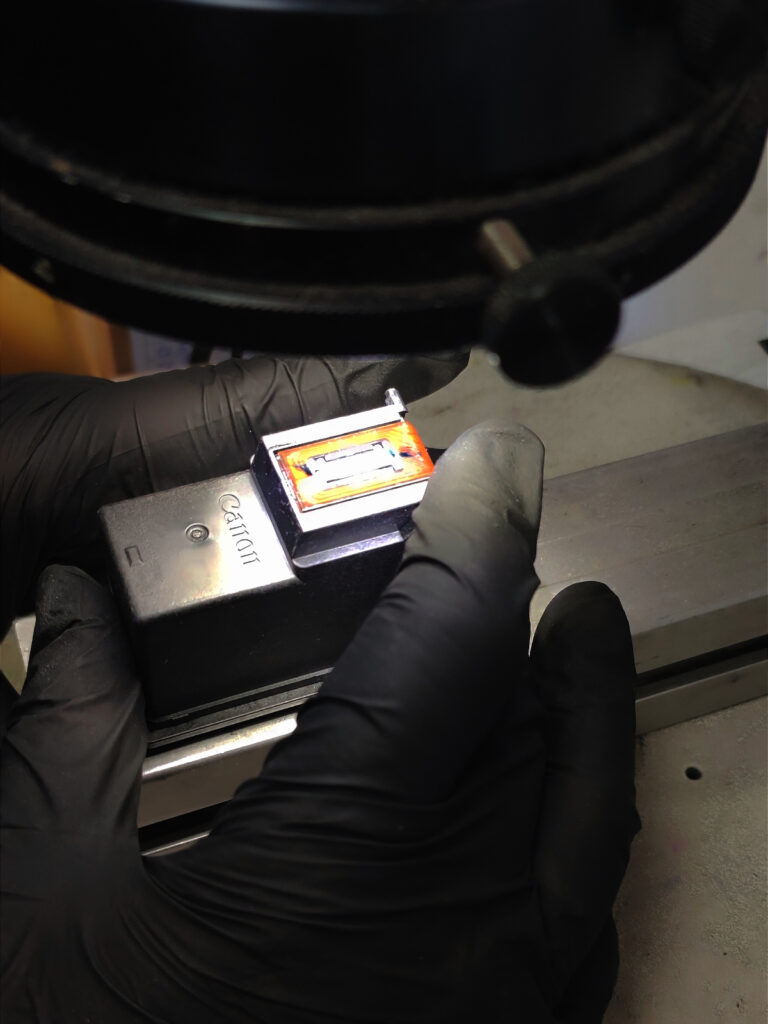

CHECKING

We evaluate the functionality of the inkjet cartridge through a visual microscope check and an electronic test.

WASHING

In this phase the tank is emptied and washed with ad hoc thinners to remove the old ink residues.

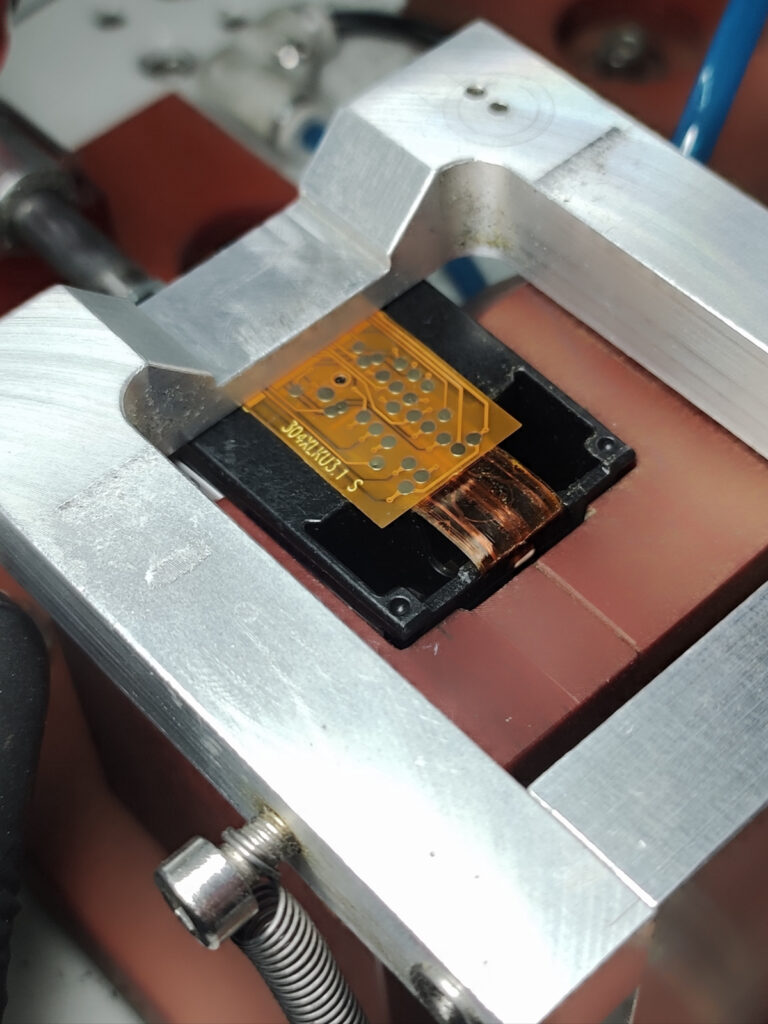

This step allows us to change the size of cartridge, increasing its capacity. With more ink, the number of pages to be printed will be greater.

In a machine with a vacuum environment, the cartridges are filled with pigmented or water-based ink.

All clean and refilled cartridges arrive at the most delicate phase: the print test, where they are examined one by one in the printers dedicated to each product.

Only those who pass this step can move on to the next level.

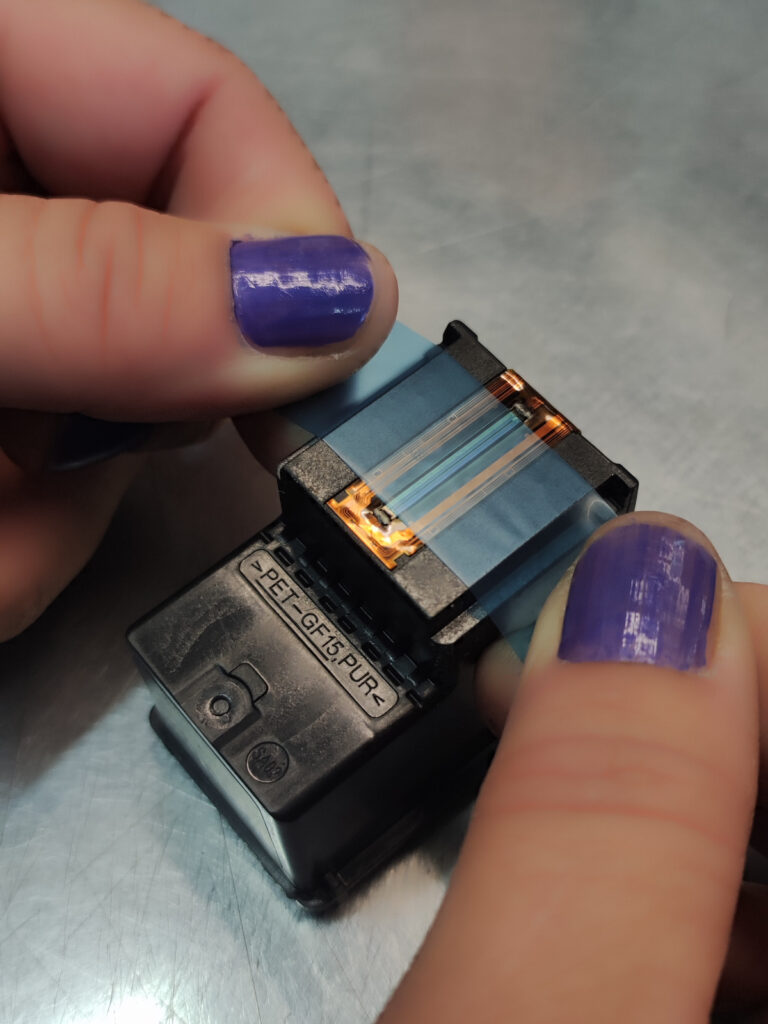

The chip is a device that allows the ink jet cartridge to communicate the exact amount of ink contained in the tank to the printer. Chip-equipped cartridges have higher yields as they accurately transmit to the printer the remaining ink level of each cartridge, facilitating the usage for the customer.

The printheads are then sealed with clips and packed in special boxes that preserve their humidity and specific weight. The remanufactured product is now ready to be labelled and shipped to our customers.

The packaging is customized according to the needs of our customers and each box is carefully assembled in the final phase of the process, which precedes shipment.